Six Steps in Manufacturing a Thick Film Hybrid

» What is a Hybrid? » Thick Film Technology » Why choose Thick Film Technology? » Thick Film Technology

STEP 1: Schematic & Artwork

Similar to that done for Printed Circuit Boards PCB’s. The schematic diagram is drawn and then the artwork made up. The artwork is then transferred to a set of screens to enable the printing and firing process sequence to commence. Below is an example of artwork that has been prepared for a new hybrid.

STEP 2: Printing & Firing

The printing and firing of the hybrid ceramics is like that done for the pottery business. A print occurs, then firing in an oven, then second print, then firing in the oven, etc. This cycle depends on the complexity of the hybrid circuit. Printing and firing multiple layers consists of conductors, resistors, insulators and surface protection glasses.

Automatic Printing

BTU Engineering specialty hybrid furnace

STEP 3: Laser Trimming

Setting the value and tolerance of resistors in the circuit by cutting a track in the fired resistor ink using a computer controlled laser beam. This can also be used for final circuit calibration and testing. A wide range of resistor values from milliohms to gigaohms along with ratings of up to tens of thousands of volts and fractional ratio tolerances can be achieved.

Laser Trimming

STEP 4: Surface mounting

Screen printing of solder paste, automated pick and place of surface mounted components on to the substrate and reflow soldering of the components.

JUKI Pick and Place machine

STEP 5: Pin attach

Adding lead frames (pins/legs) and soldering.

Hybrid with lead frames (pins/legs) attached

STEP 6: Manual Processing

Includes soldering of large components, washing, inspection, encapsulation, labelling, testing, burn-in, quality assurance, packing and shipping.

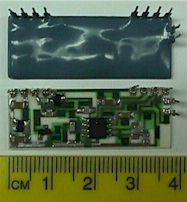

Hybrid Before & After Encapsulation

Additional Step in Manufacturing

Hybrids using semiconductor processes have the additional steps of semiconductor die attach, wire bonding and semiconductor encapsulation.

Hybrid Electronics Australia Pty. Ltd. Factory 6, 56 Smith

Road, Springvale Victoria 3171 Australia

Ph: +61 (3) 9574 2232 E-mail: hybrid@hybrid-electronics.com

© Copyright 2017 Hybrid Electronics Australia Pty Ltd. All rights reserved.

The content and format of this website are subject to copyright and may not be reproduced without permission.

Site designed and developed by Cast Creative Multimedia Solutions Pty Ltd